Product Description

The AXXIS Silver electronic initiation system is the latest expansion of AXXIS technology. AXXIS Silver incorporates numerous handling, performance, and safety improvements built upon the highly successful AXXIS GII system.

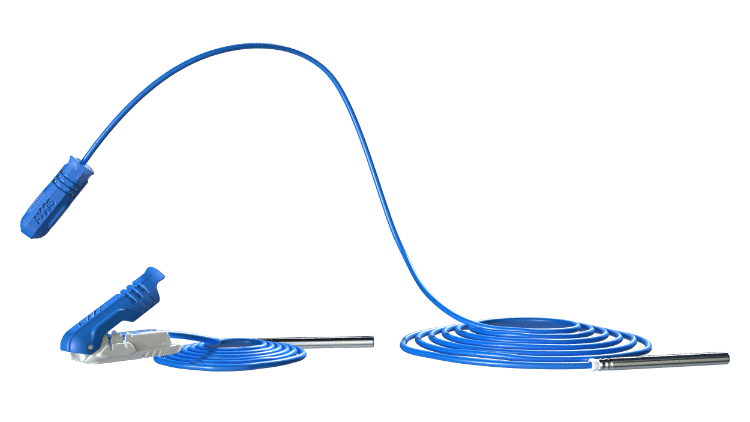

The AXXIS Silver electronic initiation system is comprised of four components:

- Electronic Delay Detonator (EDD).

- Logger.

- Blasting Box.

- Blastmap blast design software.

Application

AXXIS Silver is a cost effective solution for users wanting to upgrade from the limitations and results of non-electric initiation to the flexibility and added blast performance realized by electronic initiation.

The AXXIS Silver electronic initiation system is designed for use in most general and specialized mining, quarrying, and construction blasting applications on the surface or underground.

The AXXIS Silver electronic initiation system passes ARP 1717-1: The South African National Standard for the design and approval of EDD initiation systems for mining and civil applications.

Primary Benefits

The AXXIS Silver system is designed for high safety and security levels yet remains uncomplicated. The system is designed for blast crew ease of use as there is minimal menu driven activity to set up a blast.

EDDs safety includes dual capacitors that split the system into two. The logic capacitor is used to communicate and test the detonator and does not have enough storing energy to fire the fuse head. The firing capacitor is only used for firing. The logic capacitor has an internal shunt that when commanded switches gates from logic mode to firing mode. Only in firing mode is the firing capacitor then calibrated and charged for blasting.

The AXXIS Silver system utilises dual voltage for detonator logging and testing at low voltage. Error testing is reported by exemption thus considerably speeding up the testing and blasting process at the firing point. It takes less then two minutes to finalize a blast for firing regardless of the number of detonators.

AXXIS Silver Electronic Delay Detonator performance features include a non-volatile detonator memory. Detonators are programmed and tested during logging by writing the desired firing times and log sequence number into each detonators memory. Once detonators are programmed during logging there is no need to re-programme on powering up again. The detonator history is recorded permanently to the detonator memory making it ideal for track and trace.

AXXIS Silver EDDs have engineered copper cladded steel cables that have excellent resistant to damage and cut offs due to a balanced combination of tensile, elongation, and abrasion resistance. This results in a very low rate of misfire occurrence even under demanding hole loading conditions.

Guidelines for Use

AXXIS Silver electronic delay detonators may only be programmed, tested, and fired with AXXIS Silver Loggers and AXXIS Silver Blasting Boxes. Do not attempt to program, test, or fire AXXIS Silver EDDs with other blasting equipment. Never mix electronic delay detonators and/or components from different manufacturers.

AXXIS Silver Loggers and Blasting Boxes need to be calibrated and serviced by BME qualified personnel or providers every 2 years.

Always use AXXIS harness wire to tie-in blasts. Do not substitute similar looking harness wire as the performance specifications may not be the same.

Although BME AXXIS Silver cables are engineered and constructed for challenging work environments, care should still be exercised when loading and stemming to avoid cutting or damaging downlines.

Ground Temperature

This product may be used in ground temperatures from -40°C to a maximum of +80°C.

If the application requires use outside of this temperature range please contact a BME Technical Representative for additional guidance.

Reactive Ground

Reactive ground is typically characterised by the presence of sulphide mineralization.

If the application requires use in known reactive ground, or in untested sulphide bearing ground, please contact a BME Technical Representative for additional guidance.

Sleep Time

The recommended maximum sleep time is 21 days. Sleep time is dependent on factors such as hole depth, explosive column type, and ground water conditions.

If the application requires longer in-hole sleep time, please consult with a BME Technical Representative for guidance.

Handling and Storage

The recommended maximum sleep time is 21 days. Sleep time is dependent on factors such as hole depth, explosive column type, and ground water conditions.

If the application requires longer in-hole sleep time, please consult with a BME Technical Representative for guidance.

Product Specifications

| Column 1 | Column 2 |

|---|---|

| Delay Time Range | 0 to 15 seconds (15 000 ms) in 1ms increments |

| Delay Accuracy (COV) | 0.0067% |

| Maximum Detonators per Logger | 500 detonators per file |

| Maximum Detonators per Blasting Box | 800 detonators |

| Maximum Detonators per Blast Controller | 1600 detonators |

| Detonator Shell | Aluminum Magnesium Alloy |

| Detonator Dimensions | Nominal outer diameter = 7.5 mm |

| Nominal length = 88 mm | |

| Fits standard boosters | |

| Detonator Charge | 1.0 g |

| South Africa #8 strength | |

| Cable | HDPE outer insulation and PVC inner insulation over copper cladded steel cores |

| Operating Temperature | -40°C and +80°C |

| Hydrostatic Resistance | 7 bars for 7 days |

| Dynamic Shock Resistance | 50 MPa |

Packaging

| Column 1 | Column 2 | Column 3 | Column 5 | Column 6 |

|---|---|---|---|---|

| Detonator Cable Length | 1.1 B Units per Case | 1.1 B Max Weight per Case (kg) | 1.4 S Units per Case | 1.4 S Max Weight per Case (kg) |

| 5 m | 144 | 15.25 | 80 | 11.30 |

| 6 m | 126 | 14.95 | 80 | 11.92 |

| 8 m | 120 | 17.80 | 56 | 13.75 |

| 10 m | 104 | 18.20 | 56 | 14.35 |

| 12 m | 88 | 17.85 | 52 | 14.61 |

| 15 m | 80 | 20.20 | 56 | 18.52 |

| 20 m | 64 | 20.50 | 40 | 16.35 |

| 25 m | 48 | 18.50 | 32 | 15.51 |

| 30 m | 40 | 18.40 | 28 | 15.70 |

Custom lengths on request.

UN Classification for Transportation and Storage

Authorised Name: AXXIS Silver

Correct Shipping Name: DETONATORS, ELECTRONIC programmable for blasting

Classification: 1.1B manufactured in South Africa, UN Number: 0511

Classification: 1.4S manufactured in South Africa, UN Number: 0513

Safe Use

- Never fight explosive fires.

- Refer to Safety Data Sheet (SDS) for first aid information.

- All explosives must be transported and stored in accordance to relevant regulations.

- All explosives are classified as dangerous goods and may cause damage to property, personal harm, or death, if not used correctly.

- Always keep products away from sources of heat, sparks, flame or hot surfaces and avoid mixing with combustibles or incompatible materials.

In case of emergencies, click here to contact our team for assistance.

Disclaimer

All rights reserved. To the maximum extent permitted by law.

Omnia disclaims all liability whatsoever, whether arising in contract, delict (including negligence) or otherwise in relation to the use of any products/solutions or services and all implied warranties, terms and conditions relating to the products/solutions or services (whether implied by statue, common law or otherwise), including (without limitation) any warranty, term or condition as to accuracy, completeness, satisfactory quality, performance, fitness for purpose or any special purpose, non-infringement, information accuracy, as between Omnia and you, are hereby excluded. Omnia specifically disclaims liability and will not be responsible for, any liability or damages, howsoever arising, resulting from the use or reliance upon the information in this document.

You assume sole responsibility for results obtained from the use of the products/solutions or services, and for conclusions drawn from such use.

© Omnia Group (Pty) Ltd

Brand